Polymar

Forty-five years ago, our family business was born out of a simple conviction:

plastic injection molding is not just a technical matter, but a human adventure.

It is the meeting of an idea and the expertise needed to bring it to life.

In the early days, our workshop had a few machines, a lot of ambition, and a fierce desire to do well. We quickly realized that our strength lay not only in the precision of our parts, but also in the relationships we built with our customers.

Listening, understanding, imagining, proposing, investing.

That’s how we grew. Project after project, tool after tool, we forged bonds of trust that still guide our decisions today.

Over time, technologies have evolved, technical thermoplastics have diversified, and quality requirements have become more stringent.

We have kept pace with these developments—sometimes even staying ahead of the curve—while remaining true to our DNA:

a close-knit team, a family spirit, and a passion for a job well done.

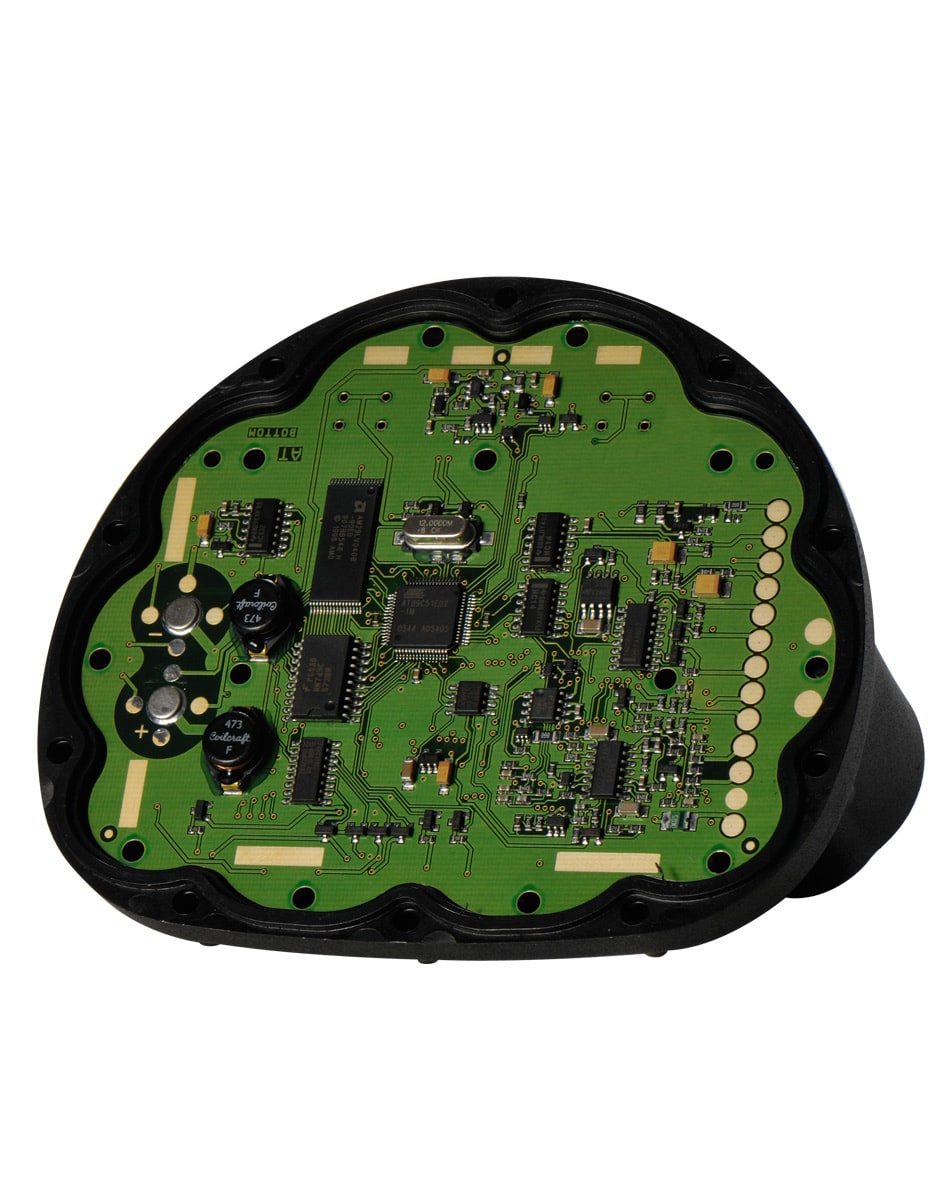

Today, we support our customers from the initial idea through to mass production, with the same commitment we had when we started out.

We analyze, design, test, optimize, produce… always with the desire to be much more than a supplier:

a reliable, creative, and committed partner.

Because for us, every injection-molded part tells a story.

The story of a customer who entrusts us with their idea.

The story of teams who transform specifications into concrete solutions.

The story of technical expertise enriched by genuine human connection.

And we are proud to continue writing this story—with you.